A fully integrated solution.

At Balyo, we believe that technology should adapt to the client, not vice versa. That’s why we have designed a solution to completely integrate into your environment.

Much more than robotic trucks, we deploy a complete architecture, adapted to the specific requirements of each client.

At the heart of the solution, the “Robot Manager” software monitors and co-ordinates the fleets of robots. As the nexus of the solution, it enables your machines, IT systems and infrastructure to communicate in real time with the autonomous material handling trucks:

Real-time Robot Fleet Management

![]() Robot Location

Robot Location

![]() Robot Mission Programming and Assigment

Robot Mission Programming and Assigment

![]() Traffic Management

Traffic Management

![]() Power Management and Charging Time Optimization

Power Management and Charging Time Optimization

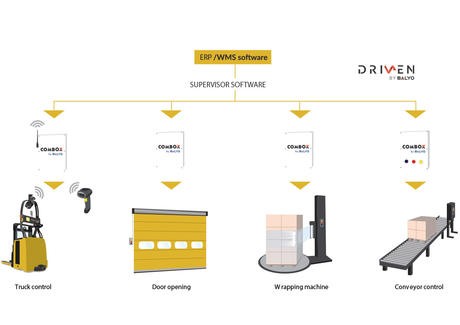

Communication with the Client Environment

![]() IT System (ERP/WMS)

IT System (ERP/WMS)

![]() Infrastructure: doors, alarms, etc.

Infrastructure: doors, alarms, etc.

![]() Machines: production line, automated wrapping machines, conveyors, etc.

Machines: production line, automated wrapping machines, conveyors, etc.

To build this architecture, we install COMBOX communication modules, which perform several functions:

![]() COMBOX Wifi/WMN/Radio, to ensure communication between Robot Manager and your robots.

COMBOX Wifi/WMN/Radio, to ensure communication between Robot Manager and your robots.

![]() COMBOX I/O ensures communication between your machines/infrastructure and your robots.

COMBOX I/O ensures communication between your machines/infrastructure and your robots.

![]() COMBOX 3 buttons, acting as an on-demand call button, so an operator can call a robot by pressing one of the buttons.

COMBOX 3 buttons, acting as an on-demand call button, so an operator can call a robot by pressing one of the buttons.

Graphical User Interface

“Robot Manager” provides clients with a real-time view of the entire circuit, and statuses and reports for missions, robots and communication modules.

Diagnostic Tool

“Robot Manager” provides clients with a complete statistical analysis of the installation based on the collection of data related to robot performance.

How do you assign a task to a robot?

For greater flexibility, the Balyo solution enables you to trigger a robot mission in a number of ways:

![]() ERP/WMS: if you use these systems, your production or warehouse management software sends a direct message to Robot Manager, which assigns a mission to the robot. E.g.: prepare a shipping area, store a specific type of pallet, etc.

ERP/WMS: if you use these systems, your production or warehouse management software sends a direct message to Robot Manager, which assigns a mission to the robot. E.g.: prepare a shipping area, store a specific type of pallet, etc.

![]() Sensors or Reports: sensors on your infrastructure or machines report the presence/absence of a pallet and trigger a robot mission. E.g.: supplying or emptying a production line.

Sensors or Reports: sensors on your infrastructure or machines report the presence/absence of a pallet and trigger a robot mission. E.g.: supplying or emptying a production line.

![]() Call Button: just pressing one of the buttons on our dedicated COMBOX tells the robot to perform a preconfigured task. E.g.: send a recently-prepared pallet to the shipping platforms.

Call Button: just pressing one of the buttons on our dedicated COMBOX tells the robot to perform a preconfigured task. E.g.: send a recently-prepared pallet to the shipping platforms.

![]() Robot Manager / IHM: you can directly trigger missions on the Robot Manager or Robot screens.

Robot Manager / IHM: you can directly trigger missions on the Robot Manager or Robot screens.

![]() Scanning Area: this function involves a robot using its front safety laser to scan a floor storage area. It then detects whether any free spaces are available for a pallet.

Scanning Area: this function involves a robot using its front safety laser to scan a floor storage area. It then detects whether any free spaces are available for a pallet.

What does this mean for you?

![]() Transparency in your operations

Transparency in your operations

![]() Tracking of your products

Tracking of your products

![]() An intuitive fleet management tool

An intuitive fleet management tool

![]() Performance follow-up for your solution

Performance follow-up for your solution

Discover our Robot Manager!